Pre-Sales

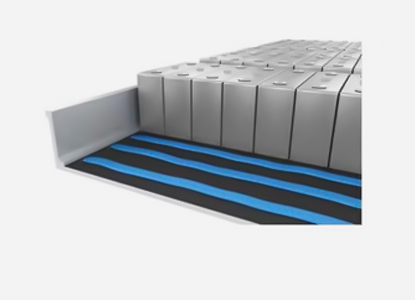

Special dispersing additives and manufacturing processes are adopted

Low density, reducing battery weight and enhancing battery life

Low hardness filler, low friction, not easy to wear the mixing equipment

Product performance | Unit | Test method | PSA-040 | PSA-120 | PSA-200 | PSA-250 |

| Color | / | Visualization | A:White B:Black | A:White B:Black | A:White B:Black | A:White B:Black |

| Viscosity | CPS.25℃ | GB/T2794 | A:20000±10000 B:20000±10000 | A:130000±50000 B:150000±50000 | A:200000±10000 B:250000±1000 | A:350000±50000 B:300000±50000 |

| Mass or volume ratio | A:B | A:B | 1:1 | 1:1 | 1:1 | 1:1 |

| Mixed density | g/cm3 | ASTM-D792 | ≤1.35 | ≤1.9 | ≤2 | ≤2.2 |

| Usage period | min | JC/T2560 | >30 | >20 | >10 | >10 |

| Hardness | ShoreA | ASTM-D2240 | 60±5 | 60±15 | 60±15 | 60±15 |

| Tensile strength | Mpa | ASTM-D412 | ≥11 | ≥11 | ≥11 | ≥11 |

| Elongation at break | % | ASTM-D412 | ≥30 | ≥10 | ≥5 | ≥5 |

Shear Bond Strength (AI6063-Gel-AL3003) | Mpa | GB/T7124 | ≥10 | ≥9 | ≥10 | ≥10 |

Shear Bond Strength (PET-Gel-PETBlue membrane) | Mpa | GB/T7124 | ≥2 | ≥2 | ≥2 | ≥2 |

| Thermal Conductivity | W/(m.k) | ASTM-D5470 | 0.4±0.1 | 1.2±0.1 | 2.0±0.2 | 2.5±0.2 |

| Flame-retardant Rating | / | UL94 | V-0 | V-0 | V-0 | V-0 |

| Volume Resistivity | (Ω·cm) | ASTM-D257 | ≥1013 | ≥1013 | ≥1013 | ≥1013 |

| RoHS standard | Yes or no | / | Correct | Correct | Correct | Correct |