Pre-Sales

With the increasing awareness of environmental protection and the rapid development of the new energy vehicle market, electric vehicles have gradually become the preferred choice for consumers. One of the core components of electric vehicles is the battery pack, whose performance directly affects the range and safety performance of electric vehicles.

At present, the thermal insulation material used for battery packs of electric vehicles is mainly aerogel. Aerogel has low thermal conductivity, low density and other characteristics, but it is expensive, low compressive strength, easy to crush and fall slag under vibration, and can not withstand the high temperature caused by battery explosion when the heat is out of control, which has brought incalculable safety hazards to electric vehicles.

In this context, Taiya Ceramic Silicone Rubber Foam emerged. It adopts advanced ceramic technology and silicone rubber materials, and is vulcanized and cross-linked to make a fireproof composite material. It has the characteristics of excellent fire resistance and flame retardancy, soft impact resistance, sound insulation and noise reduction, and low price (1/3 of aerogel). Applied in the power system of new energy vehicles, it can better achieve temperature control and electronic control management of batteries, and improve performance. It is currently considered the most suitable insulation material for thinner and more efficient new energy vehicles and power lithium batteries.

TAYA Ceramic Silicone Rubber Foam UL Yellow Card File: E516710

Product features

Cushioning and shock absorption: soft and impact resistant

·High resilience and good mechanical properties, cushioning and shock absorption

·Soft clothing provides good sealing and compensates for tolerances

Fire and thermal insulation: unable to burn through or crack

·Can withstand a flame temperature of 1000 ℃ for a long time, unable to burn through, fire-resistant and heat-insulating

·Ceramic support can be formed at temperatures above 600 ℃, without cracking and to block flame impact

·UL94 V-0 flame retardant

Durable to extreme environments: Stable performance

·Maintain high stability of performance in extreme environments such as UV, ozone, high and low temperatures

Non toxic and harmless: meets the standard

·The smoke after combustion is low smoke, halogen-free, phosphorus nitrogen free, heavy metal free, non-toxic and harmless

Compared to competitors, Taiya's advantages

With smaller pore size and higher strength, it can simultaneously achieve ultra-thin, ultra soft, and high flame retardant performance

Related experimental verification

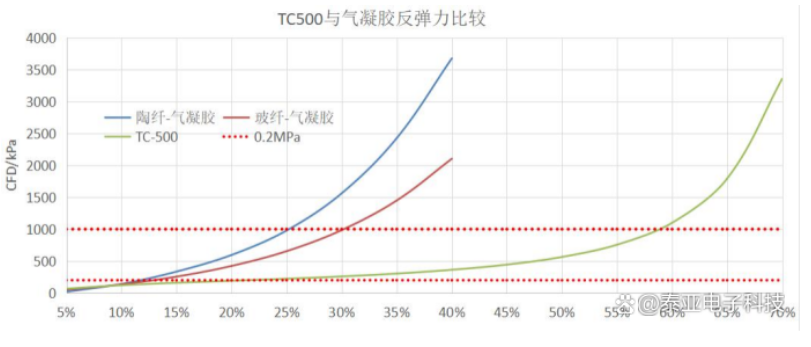

The advantages of Taiya ceramic silicone rubber foam products can be seen from the comparison between the rebound force at room temperature and the state after high-temperature ceramics (as shown in the figure below).

By comparing the rebound force of aerogel, it can be seen that at 0.2MPa~1.0MPa, the compression stroke of Taiya products is larger, and its gentle rebound force can effectively improve the cycle service life of the cell.

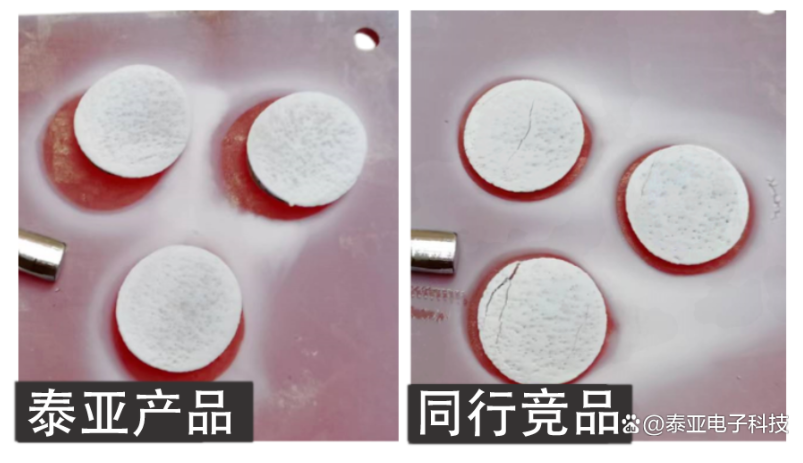

Taiya products are completely ceramic coated in a 1000 ℃ muffle furnace chamber without load, with no surface cracking (as shown in the above figure), which can provide good insulation and fire protection.

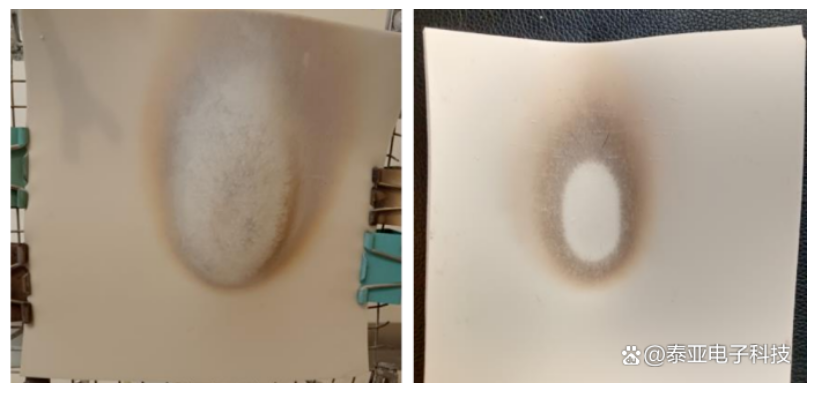

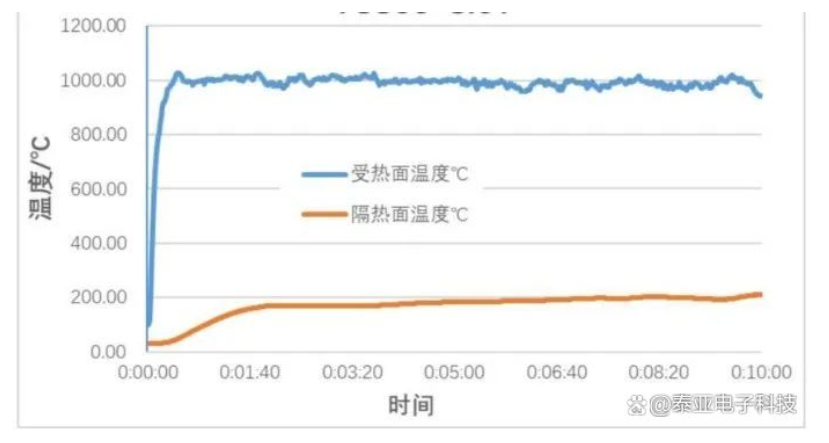

Test of flame combustion of Taiya products at 1000 ℃ for 10 minutes

Left image - Flame combustion surface of the sample

Right corner - combustion back of the sample

Temperature curves of the heated surface and back of the sample

Market applications

Taiya ceramic silicone rubber foam has a wide range of applicability. Its excellent performance makes it the preferred material in multiple fields such as automotive, electronics, aerospace, and construction. Whether used as sound insulation and thermal insulation materials in the automotive manufacturing industry, or as insulation materials in the electronics industry, Taiya Ceramic Silicone Rubber Foam can exhibit excellent performance.

For example, in the field of new energy vehicles:

The battery system of new energy vehicles requires long-term stable operation, and high-temperature environments have a significant impact on battery performance. As a high-temperature protection material, Taiya ceramic silicone foam can effectively isolate the impact of external high-temperature environment on the battery system, improve the battery's lifespan and performance.

New energy vehicles also generate high heat during operation, requiring a good insulation material to reduce energy loss. Taiya ceramic silicone foam has extremely low thermal conductivity, which can effectively isolate the temperature difference between inside and outside the car, making the indoor air conditioning system more efficient and improving energy utilization efficiency.

In addition, in terms of charging stations, it can ensure that there will be no safety issues such as leakage or fire during the charging process; In terms of cabin interior, it can effectively reduce the spread of external noise and provide a comfortable driving environment; In the face of various harsh weather conditions, such as high temperature, low temperature, humidity, etc, Taiya ceramic silicone foam can also maintain its ultra-high stability performance.

In summary, as an innovative material, Taiya ceramic silicone rubber foam has extremely high value and broad application prospects in the market. Its emergence has provided new possibilities for the manufacturing of new energy vehicles. Let's hope together that this new material can bring more convenience and safety to our lives in the future.