Pre-Sales

As is well known, organic silicon thermal conductive sealing adhesive with thermal conductivity and protective effects has become an ideal choice for thermal management auxiliary materials in new energy power batteries. However, there are still some pain points in its specific industry applications. These pain points will directly affect the production efficiency and product quality of enterprises, bringing a very negative impact. Today, we will introduce the industry pain points and related applications of thermal sealing adhesive that currently exist.

We have found pain points in the application of commercially available thermal sealing adhesive in the industry:

Four major application challenges

● Low fluidity, difficult to achieve effective sealing, unable to maximize the filling of small gaps between components, and unable to achieve ideal heat dissipation effect.

● The high internal stress of the sealing adhesive causes the magnetic core to crack, resulting in a sharp decrease in the inductance detection value and loss of its original function.

● High hardness, unable to effectively eliminate mechanical stress, and poor shock absorption effect.

● Poor adhesion, easy to fall off after long-term vibration, and cannot maintain the integrity of the sealed components.

In response to this situation, as a high-performance new material solution provider, Taiya has organized R&D personnel to invest a lot of energy and finally overcome the problem. They have developed the "new generation of organic silicon thermal conductive sealing adhesive" to solve the pain points in practical applications:

Good things come, solve pain points

——Taiya New Generation Organic Silicon Thermal Conductive Sealing Adhesive

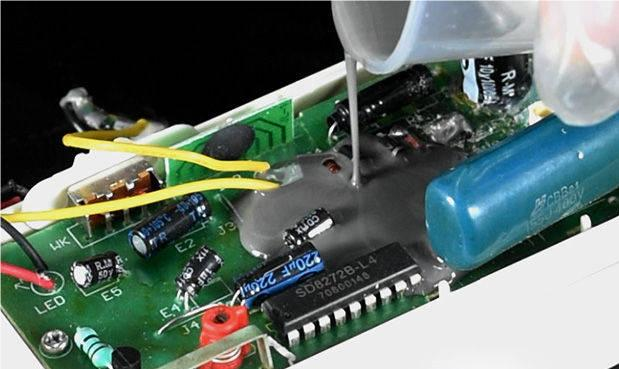

Taiya's new generation of organic silicon thermal conductive sealing adhesive can enhance the seismic, waterproof, and insulation capabilities of the product core, while bringing unparalleled thermal and heat dissipation performance, protecting the product from long-term stability and effectiveness in the working environment, extending its service life, and allowing the encapsulated electronic components to work in the best state at all times. It is suitable for a series of electronic applications such as inverters, energy storage systems, and automotive electronics in harsh operating environments, meeting the growing thermal management needs of users.

Product features

● The two-component formula is easy to store;

● 1: 1. Mixing, easy to operate;

● Curing at room temperature (or high temperature);

● It has self-adhesive properties and can achieve adhesion to components, ensuring stable and reliable sealing and thermal conductivity;

● Maintain stable performance in extreme environments such as UV, ozone, high and low temperatures;

● UL94 V-0 level flame retardant performance.

Four major advantages of Taiya products

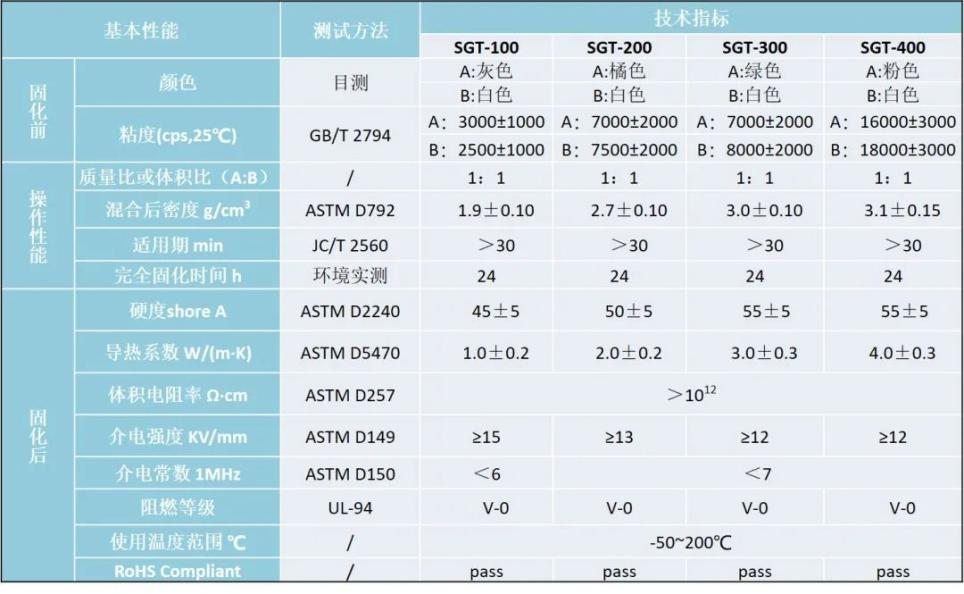

● High thermal conductivity

The measured thermal conductivity can reach 4W/mK (currently the highest on the market), which can help high-power OBC components achieve efficient heat dissipation.

● Low viscosity, high fluidity

The viscosity is very low, which brings excellent fluidity and is particularly suitable for filling small and complex pores and voids (such as gaps in automotive inductance coils), reducing the interfacial thermal resistance between colloids and components, thereby achieving more ideal heat dissipation effects

● Strong weather resistance, suitable for various extreme environmental applications

After solidification, it does not shrink and the hardness can be adjusted according to customer needs. It can better protect stress sensitive electronic components such as magnetic cores in inductors under harsh conditions such as temperature fluctuations or cold and hot shocks, providing excellent shock absorption protection.

● L has strong resistance to settling and adhesion

It has good anti settling properties, meets the application needs of high flow and high-speed dispensing, and improves production efficiency. At the same time, it has strong adhesion and can tightly adhere to the surface of components. Especially after vibration testing, it can still adsorb well on the surface of the substrate, maintaining the integrity of the sealed components

Application scenarios

Taiya's new generation of thermal conductive sealing adhesive has been widely used in the market due to its excellent performance and advantages&